Conax Technologies is a global leader in the design and manufacture of temperature sensors, compression seal fittings, and cable and harness assemblies for a broad range of industries and applications. For over 70 years, Conax customers have relied on our expertise and innovative ideas to provide both standard products and custom-designed solutions.

We understand that great minds don’t necessarily think ALIKE. Solutions and innovation happen when we think TOGETHER.

At Conax, we forge strong partnerships with our customers and take the time to understand your unique challenges. Our team of experienced engineers will apply our high standards of leading-edge design and quality manufacturing to developing a solution that helps you—and your customers—succeed. Our commitment to delivering innovative, high-quality products on time and at a competitive cost makes us your indispensable partner.

Gas Turbine Sensors & Seals

-

Exhaust Gas Sensors, Blade Path Sensors, Frame 5 Series EGT Sensor & Frame 7 Series EGT Sensor

-

Wheel-space, Disc Cavity and Compressor Discharges Thermocouples

-

Bearing Sensors and Seals

-

Air Inlet or Oil Temperature Sensor

RTD Assemblies

-

Conax Miniature Bearing Sensors (MBS)

-

Conax RTD Assemblies with B-Series Terminal Head

-

Conax RTD Assemblies with MD Disc Termination

-

Conax RTD Assemblies with PJFC-Plug/Jack Termination

-

Conax RTD Assemblies with T3/T4 Leadwire Termination

-

Conax RTD Assemblies with Terminal Head and Direct Mount

-

Conax RTD Assemblies with Terminal Heads and Adjustable Mounting

-

Conax Solutions for Steam Turbines

High Temperature Thermocouple Assemblies

Operating Temperatures up to 4200°F (2315°C)

Conax Technologies’ High Temperature Thermocouples are specifically designed for durability and reliability in high temperature applications to 4200° F (2315° C). Such applications generally involve oxidizing, reducing, inert gas or contamination atmospheres that challenge the life of the thermocouple. Conax has many years of experience in the design and manufacture of thermocouples with materials and designs to maximize the life and reliability of thermocouples in these environments. The primary characteristics of materials used in thermocouple types, sheaths, and insulations are outlined in our standard configurations below.

Furnace & Autoclave

Engineered Solutions for the Furnace and Autoclave Industry

For more than 50 years, Conax Technologies has served as a leading source of temperature sensor and pressure/vacuum sealed fittings feedthroughs for the Furnace and Autoclave Industry. Our temperature sensors and fitting/feedthrough assemblies are installed in various equipment types such as furnaces, ovens, kilns, autoclaves, freeze-dryers, vacuum furnaces, etc. Conax has various standard products for each of these equipment types but also has the capability to custom design a solution for any application or equipment. Feel free to contact our Autoclave Application Engineers today to discuss your application.

Industry Applied High Temperature Applications

Platinum thermocouple assemblies with support tubes for limit and control. Used in a vacuum-environment, heat-treat furnace with inert-gas purge.

Tungsten-rhenium Type C assemblies with sintered alpha silicon carbide sheath tubewell for use in semiconductor sintering applications.

Thermocouple for monitoring surface temperature during the manufacturing process of flat panel glass. A unique 44 AWG wire hot junction (0.002″ diameter) maximizes time response while minimizing surface contact.

Single-point platinum thermocouple with molybdenum sheath, terminated with quick disconnect male plug and flexible lead wire.

Solutions for Steam Turbines

Replacement Steam Turbine Sensors

Conax offers a complete line of OEM replacement and aftermarket equivalent sensors for steam turbines.We maintain a complete set of OEM drawings for bearing sensors, inner case sensors, outer case sensors and shell sensors (part numbers beginning with U251, U252, U253, U231, U248 and U249).

Sensors can also be manufactured and improved for any turbine manufacturer if you can provide a drawing, sketch or failed part.

-

Bearing Lube Temperature Sensor

-

U252 Series Bearing Sensor

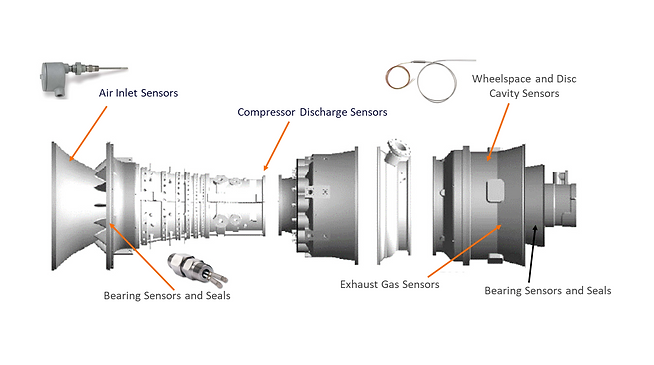

Land based Gas Turbine LM Series

Exhaust Gas Thermocouples for LM2500 and LM5000

Cost effective solution for land based gas turbines

Indispensable Conax parts for gas turbines

-

Air Inlet Sensor

-

Bearing Sensor & Seals

-

Compressor Discharge Sensor

-

Exhaust Gas Sensor

-

Wheel-space & Disc Cavity Sensor

Applications for Land Based Gas Turbines

Cables for Land Based Gas Turbines

-

•Exhaust Gas Cables (Land Base Gas Turbines and Aeroderivative engines)

-

•Sensor Interconnect Cable

Conax Certifications and Accreditations

Conax Technologies is committed to ensuring the products we design and manufacture meet or exceed the most rigorous global quality standards for the industries we serve. Achieving these certifications and accreditation reflects our dedication to maintaining the highest standard of excellence for our products and processes.